Grade 310, combining excellent high temperature properties with good ductility and weldability, is designed for high temperature service. It resists oxidation in continuous service at temperatures up to 1150 °C provided reducing sulphur gases are not present. It is also used for intermittent service at temperatures up to 1040 °C.

Grade 310S (UNS S31008) is used when the application environment involves moist corrodents in a temperature range lower than that which is normally considered "high temperature" service. The lower carbon content of 310S does reduce its high temperature strength compared to 310.

Like other austenitic grades these have excellent toughness, even down to cryogenic temperatures, although other grades are normally used in this environment.

Grade 310L (and proprietary versions of this grade), is a 0.03% maximum carbon version of 310, sometimes used for very specific corrosive environments, such as urea production.

Key Properties

These properties are specified for flat rolled product (plate, sheet and coil) in ASTM A240/A240M. Similar but not necessarily identical properties are specified for other products such as pipe and bar in their respective specifications.

Corrosion Resistance

The high chromium content - intended to increase high temperature properties - also gives these grades good aqueous corrosion resistance. The PRE is approximately 25, and seawater resistance about 22 °C, similar to that of Grade 316. Excellent resistance at normal temperatures, and when in high temperature service exhibits good resistance to oxidising and carburising atmospheres. Resists fuming nitric acid at room temperature and fused nitrates up to 425 °C.

Subject to stress corrosion cracking but more resistant than Grades 304 or 316.

Heat Resistance

Good resistance to oxidation in intermittent service in air at temperatures up to 1040 °C and 1150 °C in continuous service. Good resistance to thermal fatigue and cyclic heating. Widely used where sulphur dioxide gas is encountered at elevated temperatures. Continuous use in 425-860 °C range not recommended due to carbide precipitation, if subsequent aqueous corrosion resistance is needed, but often performs well in temperatures fluctuating above and below this range.

Grade 310 is generally used at temperatures starting from about 800 or 900 °C - above the temperatures at which 304H and 321 are effective.

Heat Treatment

Solution Treatment (Annealing) - heat to 1040-1150 °C and cool rapidly for maximum corrosion resistance. This treatment is also recommended to restore ductility after each 1000 hours of service above 650 °C, due to long term precipitation of brittle sigma phase.

These grades cannot be hardened by thermal treatment.

Welding

Good characteristics suited to all standard methods. Grade 310S electrodes generally recommended for fusion welding. AS 1554.6 pre-qualifies welding of 310 with Grade 310 rods or electrodes.

“Dual Certification”

310 and 310S are sometimes stocked in "Dual Certified" form - mainly in plate and pipe. These items have chemical and mechanical properties complying with both 310 and 310S specifications.

Applications

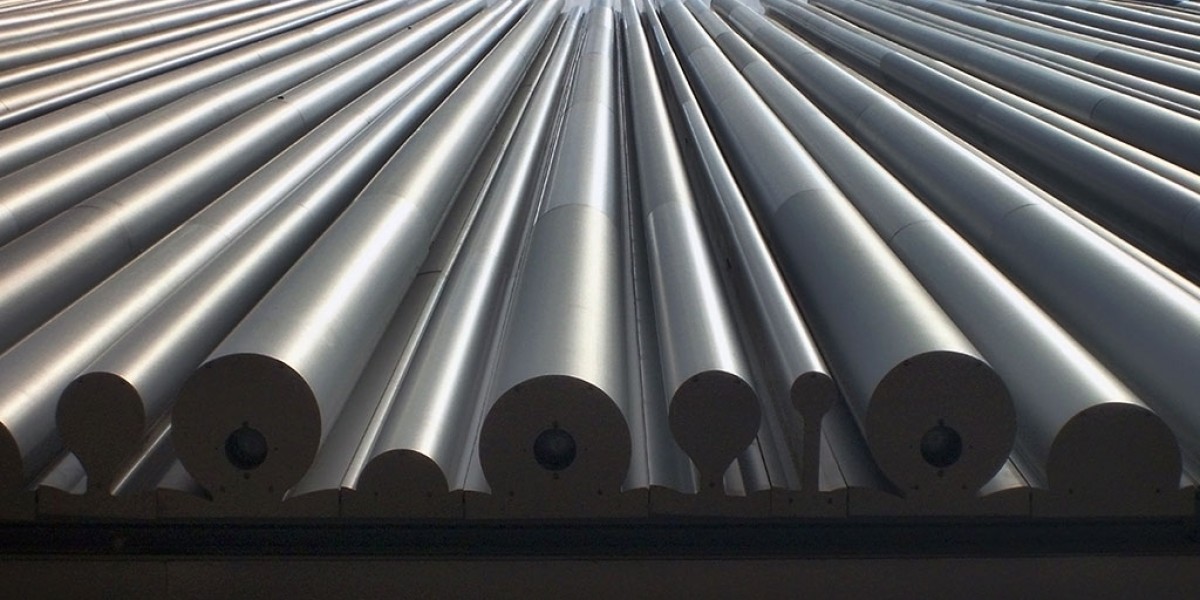

Typical applications include:

• Furnace parts

• Oil burner parts

• Carburising boxes

• Heat Treatment baskets and jigs

• Heat Exchangers

• Welding filler wire and electrodes

More Products

316 Stainless Steel

Annealing 316 stainless steels require heating to between 1900-2100°F (1038-1149°C) before rapidly quenching.

316L Stainless Steel

Grade 316L is the std molybdenum-bearing grade, 2nd in imp. to 304 amongst the austenitic stainless steels.

316Ti Stainless Steel

316Ti (UNS S31635) is a titanium stabilised version of 316 molybdenum-bearing austenitic stainless steel.

Kosmi Kotalia

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form, by injected humour, or randomised words which.

Contact Us