Stainless Steel - 301

301 stainless steel is an austenitic stainless with excellent corrosion resistance.

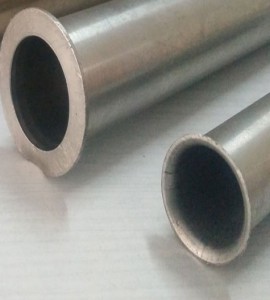

With the assistance of our highly experienced team of professionals, we trade and supply a superior quality Seamless Pipe. These pipes are extremely popular in Chemical Plants, Oil & Gas Industries, Railway Coaches And Pharmaceutical Sectors. All the offered pipes have been fabricated by trustworthy vendors in the market using best quality raw material of various metals. Our offered pipes include various features like longer shelf life, smooth finish, compact design, resistance against corrosion, etc. We are offered these pipes in various sizes, grades, standards and dimensions to meet the exact requirement of the our valued clients.

301 stainless steel is an austenitic stainless with excellent corrosion resistance.

Alloy 303 is a non-magnetic, austenitic stainless steel that is not hardenable by heat treatment.

Grade 304 is the standard "18/8" stainless; it is the most versatile and most widely used stainless steel.

Alloy 304L a T-300 series stainless steel austenitic, which has a minimum of 18% chromium and 8% nickel.

Grade 309 stainless steel has high corrosion resistance and strength compared to 304 stainless steel.

Alloy 309S are austenitic chromium-nickel stainless steels that are often used for higher temp. applications.

Grade 310, combining high temp. properties with good weldability, is designed for high temp. service.

Alloy 310S is an austenitic stainless steel developed for use in high temperature corrosion resistant applications.

Annealing 316 stainless steels require heating to between 1900-2100°F (1038-1149°C) before rapidly quenching.

Grade 316S is the std molybdenum-bearing grade, 2nd in imp. to 304 amongst the austenitic stainless steels.

316Ti (UNS S31635) is a titanium stabilised version of 316 molybdenum-bearing austenitic stainless steel.

Grade 317> stainless steel is a modified version of 316 stainless steel. It has high strength and corrosion resistance.

Alloy 317L is a molybdenum containing, low carbon austenitic stainless steel with increased additions of....

Grades 321 are the basic austenitic 18/8 steel (Grade 304) stabilised by Titanium (321) or Niobium (347) additions.

The stabilised austenitic grades 347 are similar to 304 but with Ti or Nb to imp. intergranular corrosion resistance.

Grade 410 stainless steels are containing 11.5% chromium, which provide corrosion resistance properties.

416 Stainless Steel (SS) is a martensitic free machining grade of stainless that can be hardened by heat treatment.

Grade 420 SS is a high-carbon steel with chromium of 12%. 420 can also be hardened through heat treatment.

With better strength at higher temperatures, Type 422 (S42200) is an appealing alternative to Type 403.

Grade 430 is a non-hardenable steel containing straight chromium, and belongs to the ferritic group of steels.

430F SS is a free machining version of 430 SS. Most commonly used in solenoids, 430F is ‘solenoid quality’.

Grade 431 SS are martensitic, heat-treatable grades with corrosion resistance, tensile properties.

Stainless steel grade 440A is a carbon martensitic SS that possesses good strength, hardness and wear resistance.

Stainless steels are high-alloy steels with good corrosion resistance because of large amounts of chromium present.

Grade 440C SS is a high carbon martensitic SS with strength, corrosion resistance, and wear resistance.

Grade 446 SS is a ferritic, non-heat treatable SS that has good resistance to temperature oxidation and corrosion.

More Content

Aluminium

Aluminum (also known as aluminium) is the most abundant metal element in the earth's crust. And it's a good thing, too, because we use a lot of it. About 41 million tons are smelted each year and employed in a wide arrange of applications.

Brass

Brass is a binary alloy composed of copper and zinc that has been produced for millennia and is valued for its workability, hardness, corrosion resistance and attractive appearance.

Copper

What is copper? Copper, "the red metal," is one of the most electrically conductive of all the metal elements. While its electrical properties, in combination with its ductility and malleability, have helped copper to become an integral component of the world's telecommunications.

Contact Us